Operating a laser rust removal machine can be a dangerous task. It is important to follow all safety protocols to minimize the risk of serious injury or even death.

This article will outline some of the key safety protocols that should be followed when operating laser rust removal machines, including proper training and protective gear. Additionally, it will provide details on how to safely operate and maintain these machines for optimal results and minimal risks.

By following these safety guidelines, you can ensure that your experience with laser rust removal is safe and successful.

Wear Appropriate Protective Equipment

When operating laser rust removal machines, it is essential to wear appropriate protective equipment. This includes eye protection, face masks, gloves and overalls.

These items of clothing should be made from fireproof materials to protect the worker from any sparks or flying debris that may occur during the operation of the machine. Additionally, long hair should be tied back and any jewelry must be removed as these can become entangled in machinery parts and cause injury.

Wearing a hard hat is also recommended if working around overhead machinery components such as cables or beams. Finally, workers should avoid wearing loose-fitting garments which could get caught in moving parts or obstruct their vision when using the machine controls.

By following these safety protocols and wearing the right protective equipment while operating laser rust removal machines, workers will ensure a safe environment for themselves and those around them.

Familiarize Yourself with the Machine Operation Instructions

Familiarizing yourself with the machine operation instructions is essential for safely operating a laser rust removal machine. Before beginning any work, it is important to ensure that you understand all of the relevant details and steps laid out in the manual.

A thorough review should be made of all safety protocols as well as proper usage and maintenance instructions. Knowing exactly how the equipment works will not only help protect you from harm but also extend its longevity and efficiency.

Additionally, familiarize yourself with any additional safety features or emergency shut-off procedures that may be available on your specific model of laser rust removal machine. Taking these simple steps can give you peace of mind when engaging in this type of work so be sure to make them part of your routine!

Ensure All Safety Guards are in Place

When operating laser rust removal machines, it is essential to ensure that all safety guards are in place. These guards must be checked before each use and regularly inspected for any signs of damage or wear.

Additionally, operators should always wear protective clothing and safety glasses when using these machines. Furthermore, all machine components should be properly grounded to minimize the risk of electric shock from stray currents.

Lastly, working areas must be kept clean and free of obstacles that could potentially interfere with the operation of the machine or cause injury if tripped on or over. By taking these considerations into account, operators can help ensure their safety as well as that of those around them while operating a laser rust removal machine.

Conclusion

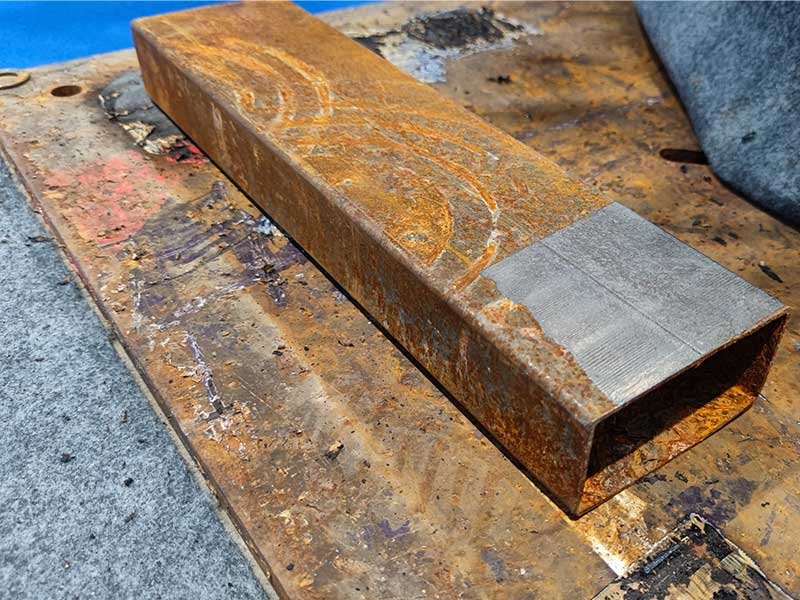

Operating Laser Rust Removal Machines can be a difficult but rewarding task. It is important to follow the safety protocols that are in place, such as wearing protective gear and ensuring proper ventilation while operating the machine. Doing so will help ensure that you remain safe and healthy while using these machines to remove rust from metal surfaces.

Taking these steps and following all safety protocols when operating laser rust removal machines will help to guarantee a successful project with minimal risk of injury or damage.